Peter Jameson

Axe handles & charcoal

13th february 2020

one ash felling day

Peter was one of the demonstrators at the One Ash felling day in February 2020. He made an axe handle (not from the one ash) and brought one along with him that he had made 22 years ago! He explains that the small split bits of wood that resulted from the process could potentially be used to make drawing charcoal. The first thing to made from the ash was a gypsie peg! You can see the ash twig that Peter used to make the peg in the above photos, he peeled and shaped it less than an hour after the tree had been felled.

He writes “I completed the peg with sliver of wood to let it set ( the gypsies also used to peg them on a thin rope for a day or three as another setting method). I hope the split does not go right up, but equally, the gypsies only wanted them to last until the next time they were passing and hawking e.g. 6 or 12 months.”

11th april 2020

“At the beginning of lockdown i unfortunately broke the handle on the dock leaf lifter whilst lifting bramble roots. As I can not buy one in lockdown I thought it's no good you are going to have to make one. I ended up making two as the quarter of a log of straight grained ash split to two billets” (billets are a short section of a log).

“The tops to the handles is from the One Ash, this was from a bit that was too twisted for a hand axe handle let alone a lopping axe handle.”

“Looking at the two billets i have left will try for a further axe handle, and will do a bit of pole lathe turning as need to turn a bit of oak before 24 th of this month so the ash will be a nice warm up exercise.”

“Another repair in these stay-at-homes times - I had a mortise chisel that had less of a handle each time I used it. I prefer a pear shaped profile (viewed end on ) handle on a mortise chisel than a round one.”

“Maybe I made this handle a bit long particularly compared to the other existing one but hey ho that was the length of the off cut so will try that length and can always cut down later.”

25th april 2020

“Today in lockdown with some of the one ash that was not in a straight enough length to make an axe handle I made two more chisel handles and four more tent pegs.”

8th may 2020 - Making handles

“This one quarter log split out, revealing an annoying spiral grain in the middle”

“Billet axe-cut to a bit less than half the log length in order to lose the spiral grain”

“The billet after using the drawknife on the shave horse”

9th may 2020 - making handles

6th june 2020

Summary of a lot out of a piece of branch wood

When selecting the piece of lop and walking it off site on felling day the plan was to make four felling axe handles but even with best efforts to read the bark one does not know how she will cleave until one opens up the log.

At the A P T (Association of Pole-lathe Turners) local group meeting in early March opening up the log there was a nasty twist on the grain about half way. So, instead of four felling axe billets by the time one had discarded ( into sack ready to add to charcoal wood ) the eight inch in the middle, one now had 8 quarter log billets about 14 inch long.

At the A P T, I made one axe handle and roughed out another hand axe size out of the best billet and the second best (I have subsequently finished the second handle).

I then busted the dockleaf lifter handle during some bramble removal in lockdown whilst I was gardening. The top cross piece is made out of the One Ash and another cross piece and handle made. With the third billet I used the draw knife to make a mortise chisel handle out of the worst eighth.

So their went number 4. I then planed up a tapering octagonal pattern chisel handle to replace a snapped one with severe wood worm, and a brass ferrule chisel bought second hand a while back. New handles were waiting for a quiet day and lock down provided that.

The tent pegs were from off cuts from cleaving the edge.

On the second weekend of may which should have been the bodgers ball and responding to the call from A P T committee to get your pole lathes out and send pictures in, the last three billets turned four pit saw handles for two tiller boxes and a replacement mortise chisel handle for the one with a light green painted large steel ferrule.

On the end of that turning was just enough wood to turn a cross piece for the coal shovel. You benefited from partly wanting to maximise the project timber, partly the timber was more precious during lock down.

There is an unwanted flat spot on the final turned chisel handle which i have put to the back , now I will have to wait and see if a tactile reference point is an advantage or a blister maker, however as that is my favourite and most used mortise chisel the handle only lasts one too two years before the top is as fury and split as the old one in the photo.

I wanted to get a lot out of the log as a tribute to Robert Penn’s book ‘The man who made things out of trees’.

3rd January 2021

I have started to make a spade handle. I had to move the setting out down a bit as on the top of the plank there was a knot just where I did not want one.

But in spite of the knot, I still had the necessary length

Today I also started to make some Charcoal form the One Ash…

First, I checked that four bags of rounds from the Ash tree crown equaled a barrel full

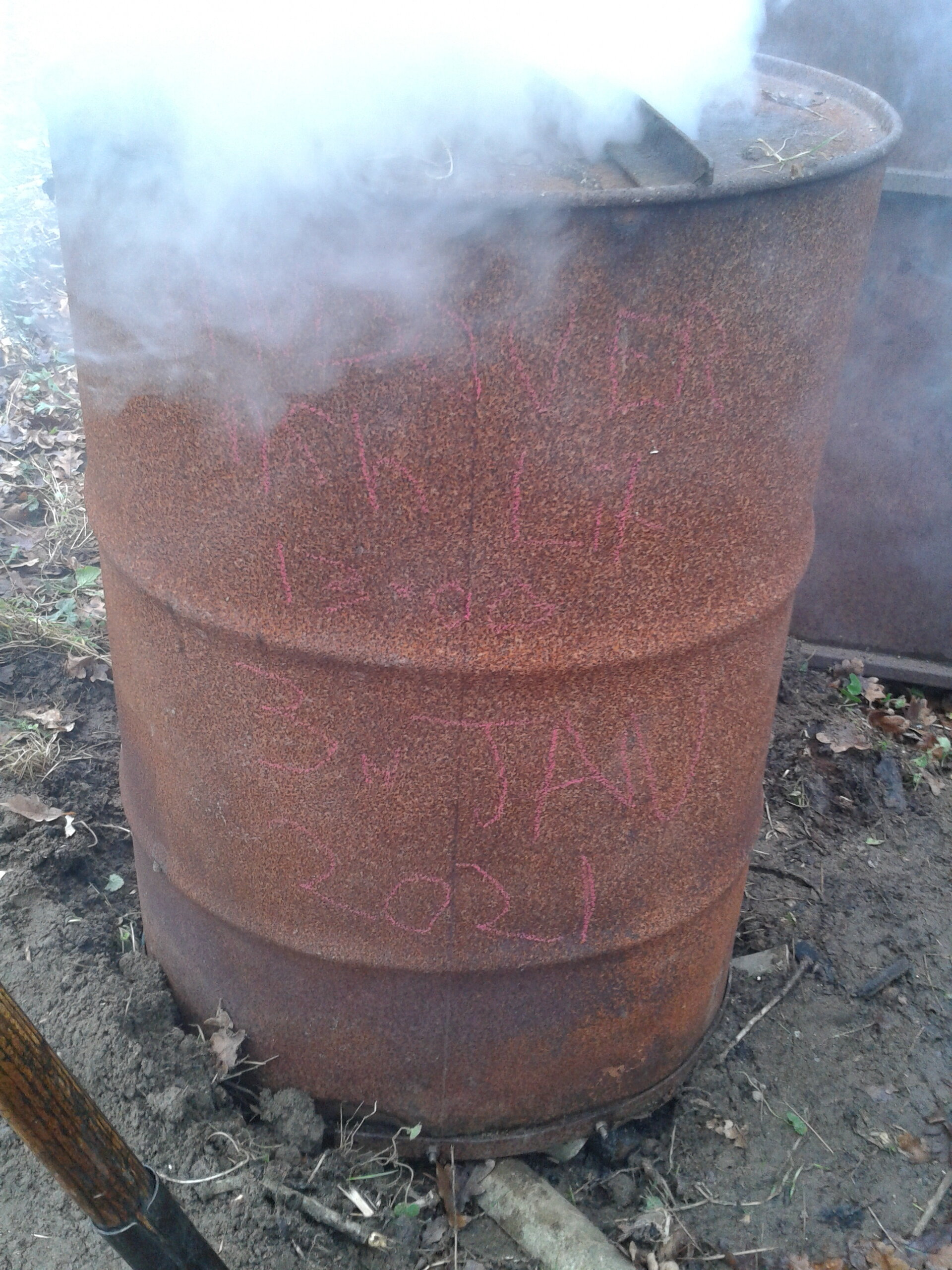

White smoke means that water is being driven out of the timber

16:30 An earthed up kiln.

I have closed down the burn and covered the top of the barrel with earth (“earthing up”). Hopefully, the little wisps are steam from the earth and not a smoke leek. Walk away and see what tomorrow brings..

Then I lit a kindling fire

The smoke has thinned out. As you can see it is still white in colour. I would prefer blue smoke at this stage but as it was lit at 13:00 hours and it is now 16:00 (half an hour over the average burn time ), I am worried that I am wicking wet ground so decided to close burn . ‘Wicking’ means to draw up liquid from a surface.

I will find out if it was the right decision tomorrow.

Next, I put the barrel over the kindling fire. Making sure to keep my hands away from the opening, I fed the ash wood into the barrel

Here you can see the back of a cold shovel glistening with condensation having been held in the smoke for ten seconds. It is difficult to photograph , but this is a technique used to indicate the speed and state of burn inside the barrel. But do it too often and one warms the shovel up too much and gets a false reading.

4th January 2021

I harvested the charcoal today. There was about 7 kg which is a good yield for a drum. I will await daylight to open the drawing charcoal box.

I took a photo but using the flash had flattened the phone battery and when I went to take a photo at the very end the phone had a funny five minutes and wiped those two and three more from yesterday!

Update: By the mystery of the cloud the lost photos have come back!..

The writing on barrel does not show up well in red chalk, but it reads the date, ‘Andover ash project’ and the time that it was lit - 13:00

The 2nd photo on the left shows the charcoal harvest by car headlights

Note the drawing charcoal container on left. There are hardly any brown ends so the wicking the damp ground decision had been right. Does not look much on ground but there is around 7kg , which is about right for a barrel burn.

To give an idea, 70 kg can come from a four foot kiln, 120kg plus in the 8 foot!

10th January 2021

On the tin lid are split small bits of the One Ash that has been converted to drawing charcoal .

I will pick up the lumpwood next time i’m in the wood. I have sieved it out and bagged it up - it is good stuff as one would expect from dry ash!

16th january 2021

The barrel sieved out to:

Two full bags of barbeque lumpwood charcoal - so over 6kg!

A small brown bag of chiminea

A small brown bag of bio char

A small brown bag of fines. Normally, 50% of this is returned to the Kiln site to improve the soil

A very small bag of brown ends or as woodland culture in Andover calls them, brands or brunts.

Lumpwood charcoal